-

Steps To Sustainable & 4th Wave Coffee Part 2 2018-04-18

Tag:Coffee At Your Side

We are very excited that our journey to sustainable coffee roasting is moving forward.

We have made the decsion to convert our factory from using gas to roast, to using electricity to roast. Our landlord is adding solar panels on our building, and has agreed to supply us with electricity from those solar panels, so in the future, our coffee will be roasted by the sun! That will make us one of the lowest carbon coffee roasters in the world! Very environmentally friendly.

The conversion from gas roasting to electricity begins with finding an electric coffee roaster. We considered importing a new machine from outside of China (Italy, Germany, USA), but none of them were well suited for our business:

•the delivery time was too long (4-6 months);•we have limited electricity, so we need a very efficient machine, none of the foreign roaster brands were willing to adjust their designs to suit our power needs;

As we were not able to find a foreign brand of roaster which satisfied all of our needs, we decided to look within China, and actually found several coffee roaster manufacturers in China. At the end of the day we decided to work with The Dong Yi company in Nanyang, Henan (yes, the hometown of Zhuge Liang and near to where Fu Hao once battled). Dongyi was willing to be flexible, and take our electricity considerations into account, and work with us to create a machine which is perfectly suited to our needs.

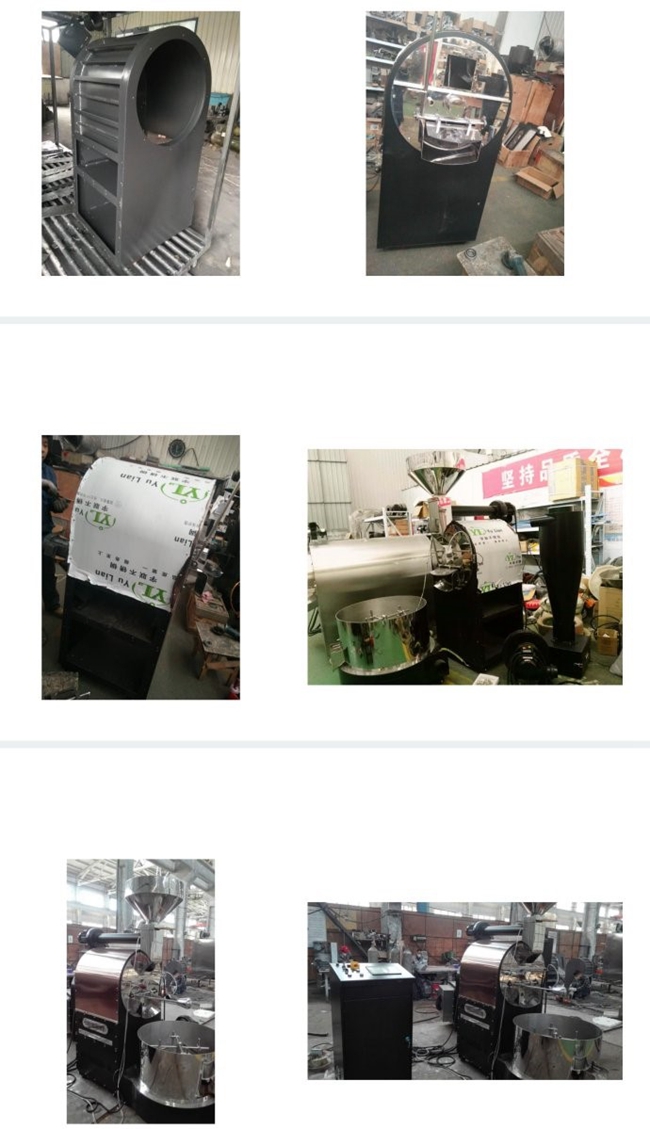

The pictures below are of the new machine.This is cool. I have never seen the inside of a coffee roaster before.

The "Body" of Our New Electric Roaster

These are pictures of various stages of assembly of our roaster.

The Process of Assembly of the Roaster

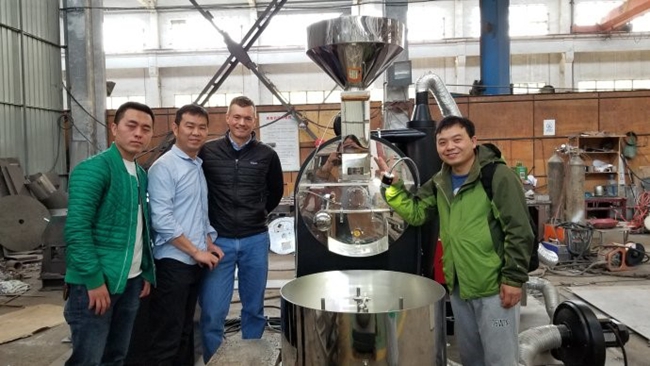

The picture below from left to right is Song Zong, the boss of Dongyi, Mr. Li Zhigang, our roast master, myself, and Mr. Li Gang, our engineer in Beijing.

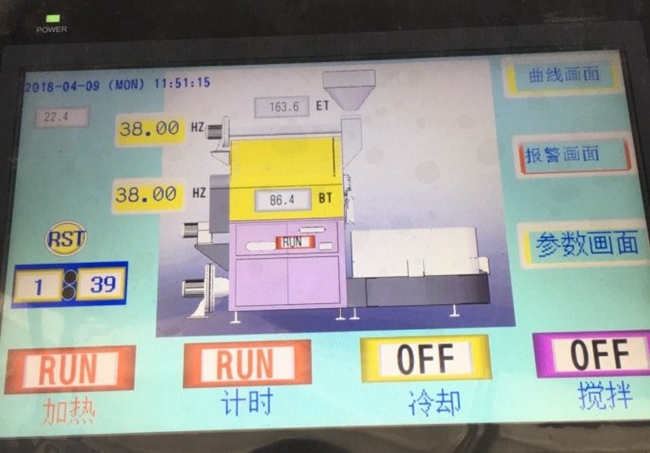

In this photo, Li Zhigang is learning how to roast using the new interface. It is an interactive display screen, and is a very cool design. This interface is exceptionally flexible to allow a lot of minute control over the coffee roasting process. Notice the coffee cups balanced on the control pannel. Li Zhigang & Li Gang had a 15 hour train ride to get there by 8:30am... so there was a lot of coffee consumed that morning.

he actual roaster control pannel is very high tech. With this new touch screen interface, we can control just about ever aspect of the roast process now.

Our Roast Master, Mr. Li Zhigang, is very excited about the potential of being able to have more control of all the inputs in the roasting process.

This level of control will allow us to take our roasting to the next level. We are very excited about this.

As you can see, the roaster uses electric heating elements to provide the heat for the roasting process. I didn't realize that my reflection was also captured in this shot. This photo is taken from the side of the roaster where the roast master stands.

As with anything, there are plusses and minuses to roasting with electricity. However, from an environmental perspective, this will allow us acutally use electricity generated by solar power to roast our coffee, which will make our roasting process very environmentally friendly. It is also borderline "high-tech"!

We will be working with our landlord to market this concept. A "green" coffee roaster in Shunyi. Very cool.This photo is taken from the other side of the roaster, so you are looking through the heater space to the other side of the roaster where the roast master stands. You can see Li Zhigang's legs if you look closely (although I don't recommend it).

When it arrives in Beijing, it will be connected to our building's electricity. Our landlord is adding solar panels soon, so this will be a very environmentally friendly roasting set up.

When it arrives in Beijing, it will be connected to our building's electricity. Our landlord is adding solar panels soon, so this will be a very environmentally friendly roasting set up.

To be continued…View (3598)