-

Coffee At Your Side - Coffee monthly newsletter section 822014-08-15

Tag:Coffee At Your Side

Coffee At Your Side - Coffee monthly newsletter section 82

Coffee production uncertainty driving prices upA leader in the coffee trade in April released a new report resulted in the Brazilian coffee crop estimate prices rise again; A recent survey showed that the price of coffee in the first quarter of 2014 rose by 63.94%. Good price reaction caused so Minas Gerais growers started selling them since the last production season began storing coffee. These coffee vending great impact on a lot of cooperatives. For example, in Watt Virginia (Varginha), from 1 million bags of coffee inventories fell 400,000 bags. By the end of April, the Brazilian market bags of coffee (60kg loaded) prices in Brazil rose to 467 yuan (210 U.S. dollars), compared to only 279 in Brazil yuan (125 U.S. dollars) in December 2013.

National Monetary Policy Council determined the coffee line of creditNational Monetary Policy Council has identified a line of credit for the 2014 coffee fund. Coffee storage industry will get the highest 1.3 billion Brazilian reals ($ 585 million) allocated quota, coffee-growing industry will get 845 million Brazilian reals ($ 380 million) allocated; coffee industry will receive 750 million acquisition of the Brazilian currency ($ 337 million) , was destroyed coffee trees restoration project will receive 20 million Brazilian reals ($ 9,000,000), and the future operation of the market will get a million Brazilian reals ($ 4.5 million). Deadline land fund and land reform programs renegotiation was likewise postponed.

Credit instruction manual can strengthen sustainable developmentCoordinated by the Brazilian P & A's sustainable coffee project IDH (SCP) has released a line of credit to enhance instruction manual coffee growers sustainability. Booklet 15 enumerated and described the credit by the federal government and major coffee producing regions specified. 21 guidelines cover a broad sustainable development, support different aspects of small family farmers, gender equality and youth participation, which helps to understand why Brazil is already the world's largest source of origin and sustainable coffee is ready at this a field can have greater development.Connie Long new minimum priceAccording to Espirito Santo growers requirements and is based on research Conab, the Brazilian Ministry of Agriculture decided to 60kg bags Connie Long (Robusta) lowest price currency transferred to 180.80 from 156.57 Brazil Brazilian currency ($ 70.50) on ($ 81.50), an increase of 15.5%, that is, the lowest price per ton equals $ 1,350.Minas Gerais region demonstrated the potential of Connie Long plantedMaita M. Jonas began extensive research plots in 2003 demonstrated the enormous potential of the region to become Connie Long-producing areas, due to the popularity of this region of Brazil hot weather, planting Connie Long 比阿拉比卡 more suitable. In order to promote the production Connie Long, Epamig (Agricultural Research Institute of Minas Gerais) is being distributed to selected growers 10000 Connie Long seedlings as part of a pilot project; second step will be to expand production the state's other cities. Maita M. Jonas Coney Long is expected to put into operation in 2016.Connie Long thrive in southern BahiaAfter experiencing a prolonged drought in the southern region of Bahia, abundant rainfall contribute to Connie Long yields. For example, growers in Eunápolis hope this year's production could reach 95 bags (5.7 tons) / ha, which increased by 30% compared to when the area suffered the most serious crisis of last year. Coffee trees from the area now, this year's production is expected to Connie Long grew 11 percent to 800,000 bags.

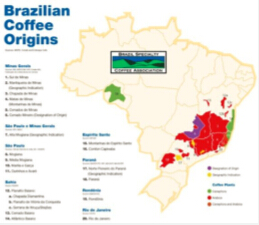

Brazil launched the latest source of origin MapBy the Brazilian Specialty Coffee Association research and support state and federal agencies developed under the latest source of origin Brazilian coffee map unveiled at the Seattle SCAA fairs. Map updated in Brazil contains 20 major coffee producing areas - Minas Gerais 6, St. Paul 4, the boundary Minas and Sao Paulo 1, Bahia 3, St. Espiritu state 2, Parana 2, Rondonia one, Rio de Janeiro 1 - also contains alta Maggie Carolina, a pioneer in northern Parana region of geographical indications and cerrado source of origin. Each coffee-producing areas of the map and instructions available at www.bsca.com.br website.

The SCAA Coffee Cerrado region of origin fairs names widely soughtSeattle held on April 24-27, the 26th SCAA fairs, coffee names of origin Cerrado region of Minas Gerais widely sought after. Cerrado region includes 55 towns and 4,500 coffee growers, coffee production an average of more than 5 million bags per year. In order to obtain a certificate issued by the Federation cerrado, coffee growers must comply with a series of regulations, including environmental protection and social responsibility practice, they need to be stored in a warehouse coffee federation, and each of Arabica planting elevation higher than 800 m (2,600 ft).Coffee coffee industry plagued by illegal trade in seedsProcafé Foundation and the National Coffee Association noted that Brazil illegally exported to other countries in the coffee seed increase. This species usually involves illegal acts are those developed through years of research institutions in Brazil and showed a high resistance to pests and or seed / high yield, which may have constituted a phytosanitary threat. Procafé estimated that in 2013 about the coffee seeds smuggled 30 tons, the equivalent of 120 million seeds will grow 30,000 hectares (7.4 million acres) of land. Part of the smuggled from other countries to be included in Brazil's coffee tour representatives, including some involved in cooperation projects in the staff. In the formal market, the cost price of 1kg of seeds in Brazil currency 25 yuan to 30 yuan ($ 11 to $ 13.5) between.The future of small quantities of coffee growers and small farmersWith the strong trend of small quantities of coffee cultivation and benefits obtained from the face of these coffee growers can no longer cover their cost of living increases and raise expectations, when people without asking whether this is a small family farmers out of the woods, to help their children achieve the desired city life in a solution? The answer is that small quantities of coffee plantations helpful but far from being a clear solution.At issue in the highly competitive market of small coffee growers face is the lack of household income; small quantities of coffee plantations may have some help, but their niche market is very short. Moreover, given the high price niche market may be an excuse to avoid reducing costs, thus planting small quantities will not be able to increase productivity.Even small quantities of planting also requires a certain size. According to their own circumstances, they must form a certain scale of small family farmers' groups. Small quantities of planting must also determine shipping matters, because their coffee production is far from a container capacity. Even the direct trade also need to meet certain minimum size requirements, but can not get alone guarantee delivery price premium protection. So what's the solution be?To ensure that small farmers have a viable future growers real challenge is to create some market policies rather than subsidies to ensure that they are able to achieve a certain scale and production efficiency without losing their identity. Convinced that the traditional production, processing systems and labor-intensive practice just to ensure the quality of sustainability indicators rather than business. On the contrary, these approaches will lead to future growers suffered far more than most people imagine poverty. Do not have unreal business idea, namely, that it will be more professional and more competitive, and will be better in all aspects, including production, including!Growers will gather together to make it the best way to get economies of scale in purchasing, marketing and delivery technologies that cooperatives, but not always successful cooperatives case columns. Cooperatives worked well in some countries and in some countries it is not so good, while in other countries it almost did not see. Even in some of the major producing countries, such as Brazil, co-operation in some areas than in other parts of the good. Although the law in most countries the minimum requirements are clearly defined profit cooperatives, but usually financial aspects, not restrictions on cooperatives.Another alternative is to coffee growers cooperative organization Association, which requires less and quite profitable, in some countries and regions, widely favored. But it seems more for market development, publicity and promotion, rather than the pursuit of economies of scale in production, processing and marketing.In addition to the institutional and financial means to attract growers to work together and integrate the business is the easiest means of sharing costs, especially the kind of relationship fixed. Integration growers most common way is to buy planting material inputs - fertilizers, pesticides, etc. - sharing equipment, as well as sales of coffee together. This seems obvious, but the growers to focus together to make these things is not easy, because they lack confidence in each other, leading to poor management and a lack of legal and fiscal framework to support the operation of the above-mentioned contents. Central processing plants, such as peeling / cleaning or drying equipment may play development, the role of organized groups of seed growers and catalyst.To share investment and processing costs, and to facilitate small farmers, specialty coffee and coffee growers of high-quality central processing plants often make the initial reason most growers gathered together. After the first group activities either upward integration - buy planting materials and shared investment in other aspects of the equipment, such as sprinkler irrigation and harvesting equipment, or down consolidation, sales of coffee, or both. The latter is the most difficult to achieve, even if the identity of each batch of coffee beans are entered in the traceability system. Even if joint processing does not weaken or strengthen other collective action, but on the behavior of this one was shared their favorite massive economic justified. For example, given a thousand people accompanied by planting small peeling machine required investment may be needed investment to build the same production capacity of 10-15 times the central peeling plants, that is, on a one thousand growers peeling products processing.Now is the governments, development agencies, and even the sustainability standards organizations began to devote more attention to the small family grower groups and / or integrated organization of the time, in order to avoid in the near future, they either disappear or perish for large business labor suppliers. Cooperatives, associations, central processing plant in the path of development and certification bodies is correct, but the institutional and financial support, and innovative forms of association also needs to speed up the process, before it is too late.Small quantities of coffee processingIndividual growers or central processing plant in the use of wet processing equipment Pinhalense small quantities of coffee and coffee can fully retain their original characteristics and quality characteristics.

The smallest models ecoflex production line or peeling machine --ecoflex-1X-- have the same kind of large equipment features: - immature fruit isolated - small coffee injury - no shelled beans pomace - shelled beans skinless slag, and - preceding the lowest water consumption can access these peeling machines with processing capacity to match the LSC-5PX mechanical siphon machine, the segment connecting DMPE- 0X mechanical unglued machine.Pinhalense latest separating rotary drum dryers have been designed for the processing of different sizes and characteristics of small batches of coffee, respectively.

Small quantities of nuts and / or shelled shelling beans and / or polishing and size-fractionated by Pinhalense of C2DPRC to complete, it is a collection of shelling, polishing, recycling and particle size classification functions. Although the available time is not long, but some countries have become C2DPRC processing small batches of coffee - preferred device from nuts or shelled beans into quality coffee exports.

Similarly, there are some small family growers want to process their own small batches of coffee, it would need something like a small device as shown above, and some small family farmers, medium-scale cultivation, consisting of large-scale growers and exporters groups, that they have to install more high-capacity production line to process small batches of coffee and coffee separately and to fully retain the original quality and features. In this case, Pinhalense recommended with mechanical siphon LSC-10PX and DMPE-3X's ecoflex-2X and 4X the peeling machine combination. It is also recommended separating large rotary drum dryer SRE, as is a station or more than one, depending on the batch of small quantities of coffee and number, of course, can also select a monolithic SRE dryer series.Even the shell bean processing line capacity from 4 t / h to 12 t / h, and even 18 tons / hour of the large growers and exporters of all sizes, also purchased a small Pinhalense production line for processing small quantities and certification batches of coffee. They are to be processed according to the number of batches and use of production capacity from 0.5 tons / hour to 2.0 tons / hour CON shelling machine, DEPOS shelling - polishing machine, PFA particle size grading machine and MVF gravity sorter.Related articles you might like:

View (6928)